Using LabVIEW and Process Controller Communication Libraries to Automate Pasta Making

One of our customers wanted to upgrade their operation by adding centralized control and monitoring over multiple dryers in a pasta making operation. Because the operation is a relatively small volume producer, owned by a non-profit entity, cost was a strong issue in choosing a solution, but the customer desired a flexible, modular and capable solution.

Spaghetti Exiting the Extruder

The pasta dryers require control over temperature and humidity in multiple stages as the pasta cools and dries. After being extruded into the desired shape (spaghetti, linguini, lasagna noodles, etc.) the pasta hangs on long bars as it moves from one stage of the process to the next.

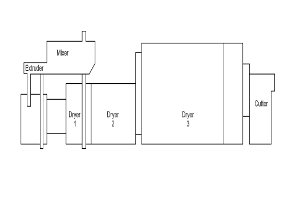

Pasta Plant Schematic

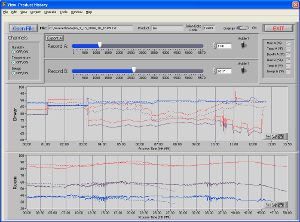

All the controllers were networked together in a simple daisy-chain with the serial interface installed in a PC and assigned unique addresses via the front panel on each controller. A program was written to monitor temperature and humidity values, to control setpoints and recipes,

LabVIEW allows real-time view of pasta drying conditions

RS-485 communication using the Process Controller Communication Libraries to facilitate communications with LabVIEW™ provided for a quick development time and the ability to quickly add or change features, like adding alarm management.

The system has since been upgraded to add a counter which allows for totalizing the amount of pasta produced. The counter also allows batch drying histories to be extracted from the temperature and humidity data in the dryers so that conditions for each individual bar of pasta can be monitored. The counter also communicates with LabVIEW through RS-485 communication using Integrated Pro’s Panel Meter Communication Library for LabVIEW.

Learn More:

- Download the complete article with pictures

- Read about Process Controller Libraries

- RS-485 Networking Tips